How to Fix Car Air Conditioner: DIY Troubleshooting

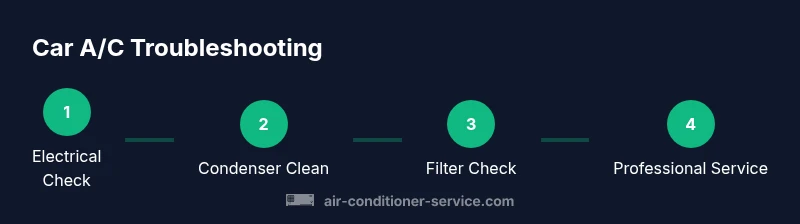

A practical, step-by-step guide to diagnosing and addressing common car A/C problems. Learn safety tips, essential checks, and when to seek professional help from Air Conditioner Service.

Learn practical, step-by-step methods to diagnose and fix common car A/C problems. You’ll verify electrical power, inspect airflow, identify leaks or worn components, and determine when a refrigerant recharge or professional service is needed. This guide emphasizes safety and starting with safe, non-destructive checks before any component replacement. Refrigerant work requires certification, so plan to involve a skilled technician if a recharge is required.

Understanding how car A/C works

The automotive air conditioning system is a closed loop that uses a refrigerant to absorb heat from inside the cabin and release it outside. Key components include the compressor, condenser, expansion device (valve or orifice tube), evaporator, blower, and the refrigerant lines that connect everything. When all parts are functioning, you’ll feel cold air emerge from the dash vents within minutes of turning on the A/C. According to Air Conditioner Service, car A/C problems often stem from leaks, faulty electricals, or simple airflow blockages. Understanding the flow path helps you diagnose issues more accurately and communicate with a professional if needed. Always ensure the car is off before inspecting electrical parts, and wear eye protection when checking cooling components.

Common symptoms and what they mean

Not cooling, warm air, or inconsistent temperatures can arise from several causes. A weak blower may deliver little airflow; a faulty compressor clutch can fail to engage; a blocked condenser reduces heat rejection; low refrigerant from leaks reduces cooling intensity. A noise from the engine bay when the A/C is on could indicate bearing wear or a failing compressor. Before assuming a major repair, confirm that the blower and vents are working, the blend doors inside the dash aren’t stuck, and there are no obvious leaks at service ports. If outside temperatures are high, you might notice cooler air when the engine is at higher RPMs due to increased refrigerant pressure. The goal is to separate electrical, airflow, and refrigerant-related issues.

Quick diagnostic checklist you can perform safely

This section provides safe, non-destructive checks you can do at home. Start with the electrical side: verify the climate control settings, inspect fuses and relays, and listen for the compressor clutch engaging when the A/C is turned on. Next, inspect for loose wires, damaged hoses, or a dirty condenser that restricts airflow. Finally, assess airflow by removing the cabin filter and noting any improvement in air quantity or quality; if airflow improves, the cabin filter is likely clogged. If you notice leaks, or if you smell refrigerant, stop and contact a professional.

Electrical and fuse checks

Begin with the car’s battery off for safety, then locate the A/C fuse and relay related to the compressor. Remove and inspect for a blown element or corrosion on the terminals; replace with the same amperage rating if necessary. Check the wiring harnesses for loose connections and ensure the relay clicks when you toggle the A/C switch. A faulty relay or blown fuse is a common cause of no-cool symptoms and is often the easiest fix. If the fuse or relay repeatedly fails, there may be an underlying short or overload from a failing component.

Inspecting condenser fins and airflow

The condenser sits in front of the radiator and must have clear airflow to shed heat effectively. Inspect for dirt, leaves, or bent fins; use a soft brush or compressed air to clean gently. Ensure the cooling fan at the condenser is operating when the engine is running and the A/C is engaged. Debris blocking airflow or a non-working condenser fan can dramatically reduce cooling performance, even if the rest of the system is intact. After cleaning, recheck performance before proceeding to more invasive checks.

Cabin air filter and HVAC airflow troubleshooting

A clogged cabin air filter reduces airflow and can worsen cooling performance, especially on high-humidity days. Locate the filter housing behind the glove box or under the dash, remove the old filter, and inspect for dirt and debris. Replace it with the correct filter type for your vehicle. While you’re at it, check the HVAC mode settings and blend doors for correct operation; a stuck door can produce inconsistent temperatures. Clean airflow paths to ensure the evaporator receives adequate air.

Refrigerant considerations and safety

Refrigerant handling requires specialized training and equipment. If the system is low on refrigerant due to a leak, a certified technician is needed to locate the leak, evacuate the system safely, and recharge with the correct refrigerant and oil. Do not attempt to recharge or vent refrigerant yourself; improper handling can cause environmental harm and personal injury. This section covers signs that refrigerant work may be required, such as persistent warm air, steadily decreasing cooling capacity, or visible leaks around service ports.

When to call a professional and get quotes

If basic electrical, airflow, and filter checks do not restore cooling, or you notice freezing or unusual noises, schedule a professional diagnostic. A licensed technician can perform a precise refrigerant charge, assess the compressor and clutch, inspect the condenser, and verify system seals. When requesting quotes, ask for a full diagnostic report, estimated repair or replacement costs, and warranty terms on parts and labor. Document symptoms and timing to help the shop pinpoint the issue quickly.

Maintenance to prevent future failures

Regular maintenance of your car’s A/C system reduces the risk of sudden failures. Schedule periodic cabin filter replacements, keep the condenser area clear of debris, and have a professional inspect the serpentine belt and compressor clutch as part of routine service. Run the A/C for several minutes every week even during off-season to maintain lubrication and prevent seals from drying out. Maintaining the system early can save you from costly repairs later and keeps you comfortable year-round.

Tools & Materials

- Basic tool set (socket wrench, pliers, screwdrivers)(Includes Phillips and flat-head; sizes vary by vehicle)

- Digital refrigerant pressure gauge(For reading system pressures; do not open the system without proper training)

- Safety glasses(Eye protection during inspections)

- Gloves suitable for automotive work(Chemical resistant is ideal)

- Replacement cabin air filter(If clogged, replace to improve airflow)

- Owner's manual or service manual for your vehicle(Verify component locations and specs)

- Lubricant or penetrating oil(Use sparingly on fasteners)

Steps

Estimated time: 60-90 minutes

- 1

Check power and fuses

With the car off, locate the A/C fuse/relay related to the compressor and inspect for signs of a blown fuse or corrosion. Replace with the same amperage if necessary. Confirm the electrical supply to the climate control system is intact before deeper checks.

Tip: Use a multimeter or fuse tester to confirm continuity and avoid guessing. - 2

Test the compressor clutch

Start the engine, set the A/C to maximum cool, and listen for the compressor clutch engaging. If the clutch does not engage, inspect the serpentine belt tension and inspect the clutch coil wiring for damage. Do not run the system with a slipping belt for long.

Tip: A slipping belt can overheat and cause further damage; replace promptly. - 3

Check blower and cabin airflow

Turn on the blower and set to all modes to confirm consistent airflow. If there is little or no air, inspect the blower motor and the dash blend doors for obstruction or failure. Clear any debris and confirm the blower is delivering air to the evaporator.

Tip: If airflow improves after removing the cabin filter, replace it and test again. - 4

Inspect condenser area for debris

Check the condenser fins in front of the radiator for dirt, leaves, or bending. Gently clean with a soft brush or low-pressure air flow to restore heat exchange. Ensure there is a clear path for air to move through the condenser when the engine is running.

Tip: Never use high-pressure water directly on fins; it can bend them. - 5

Verify condenser fan operation

With the A/C on, observe the condenser fan to ensure it spins. If the fan is inactive, inspect the fan relay and wiring. A non-working condenser fan reduces heat rejection and cooling efficiency.

Tip: Check for debris or leaf build-up around the fan blades. - 6

Check for refrigerant leaks

Visually inspect service ports and hoses for oil leaks or dye traces around joints. A persistent leak will require a professional leak test and refrigerant recharge. Do not attempt to seal leaks yourself.

Tip: Mark any observed leaks with tape and note the location for the technician. - 7

Inspect cabin air filter

Remove and inspect the cabin air filter for dirt and clogging. Replace if dirty to restore airflow and improve cooling efficiency. Reinstall the filter and test A/C performance.

Tip: Keep a spare filter on hand for quick replacements. - 8

Assess refrigerant service ports and lines

Inspect service ports and lines for damage or signs of corrosion. If the system pressure seems off or you notice hissing sounds, stop and seek professional service. Handling refrigerant without training is hazardous.

Tip: Avoid touching color-coded service ports with bare hands. - 9

Decide on DIY vs professional repair

If basic checks don’t restore cooling, evaluate the cost and risk of DIY fixes versus professional repair. For most refrigerant-related issues, consult a licensed technician to prevent environmental and personal safety risks.

Tip: Request a diagnostic report and warranty details when hiring a pro. - 10

Plan next steps and safety considerations

Document symptoms, take notes on noises, smells, or temperature changes, and plan a workshop visit if needed. Prioritize safety by disconnecting the battery when inspecting electrical components and never vent refrigerant.

Tip: Prepare questions in advance to maximize the value of the diagnostic visit.

Common Questions

What are common causes of a car A/C not cooling?

Common causes include electrical issues (fuses, relays), a failing compressor clutch, leaks in the refrigerant system, a clogged condenser, or a blocked cabin air filter. Start with safety checks and basic airflow before pursuing repairs.

Common causes are electrical problems, a failed compressor clutch, leaks, and a clogged condenser.

Is it safe to recharge car AC refrigerant myself?

Recharging refrigerant should only be done by a certified technician. Improper handling can cause injuries and damage the system. If you suspect low refrigerant, have a pro perform a leak test and recharge.

Only a trained technician should recharge refrigerant.

How long does a basic A/C diagnostic take?

A basic diagnostic and some safe checks can take around 30-60 minutes, depending on the vehicle and symptoms presented. More complex repairs require additional time.

Usually 30 to 60 minutes for a basic check.

What can I do to prevent A/C failures?

Replace cabin air filters regularly, keep the condenser clear of debris, and address leaks promptly if detected. Regular inspections help maintain cooling efficiency.

Regular maintenance helps prevent failures.

When should I seek professional help?

If you notice persistent not-cooling, unusual noises, or refrigerant smells, contact a professional for a thorough diagnosis and safe refrigerant handling.

If issues persist or you smell refrigerant, call a pro.

Can a bad condenser cause poor cooling even if the compressor is fine?

Yes. A blocked or damaged condenser can prevent heat rejection, leading to reduced cooling even with a functional compressor.

A bad condenser can stop cooling properly.

Watch Video

The Essentials

- Start with electrical and airflow checks to identify quick fixes

- Do not handle refrigerant without proper certification

- Leaks or a failing condenser require professional service

- Regular maintenance reduces the risk of future failures