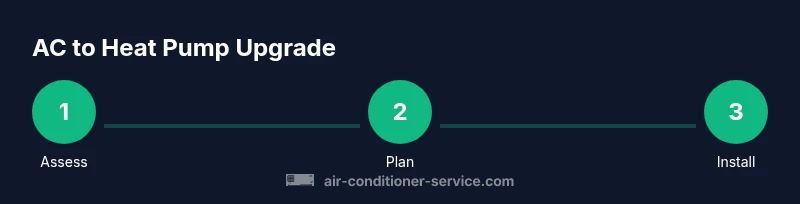

Air Conditioner to Heat Pump: Practical Conversion Guide

Learn how to switch from an air conditioner to a heat pump with practical steps, options, and maintenance tips. This guide covers sizing, installation, and energy efficiency for homeowners.

To switch from an air conditioner to a heat pump, start with a climate check, existing ducts, and electrical readiness. This guide covers upgrade options (air-source vs ducted), the step-by-step installation process, and typical costs. The Air Conditioner Service Team notes that proper sizing and professional installation are essential for efficiency and reliability.

What this transition means for homes

Switching from an air conditioner to a heat pump can dramatically reshape your home's heating and cooling approach. If you’re considering the transition from air conditioner to heat pump, you’re weighing a device that provides both cooling and heating in one package. The goal is to maintain comfort while improving energy efficiency and reducing operating costs over time. According to Air Conditioner Service, the success of this upgrade hinges on correct sizing, climate suitability, and proper installation. This section explains what changes to expect, how a heat pump operates differently from a traditional A/C, and how to assess whether your home is a good candidate. You’ll learn about the two broad families of heat pumps—air-source and ground-source—and how each fits different climates, budgets, and existing ductwork. We’ll also cover ducted vs. ductless configurations to help you decide whether a full home retrofit is necessary or if a targeted solution suffices. In short, the switch from air conditioner to heat pump is not a single purchase but a system upgrade that touches electrical, ventilation, and climate control planning.

How heat pumps differ in operation and benefits

Heat pumps move heat rather than generate it, so they can deliver warmth in winter by extracting heat from outside air or the ground. In cooling mode they function similarly to an air conditioner but with a reverse cycle that swaps the flow of refrigerant. This dual functionality makes heat pumps attractive for homeowners seeking year-round comfort. They also tend to operate more quietly and offer advanced controls, zoning, and smart thermostats. However, performance depends on outdoor temperatures; some models struggle in extreme cold unless they have supplemental resistance heating or are paired with a gas furnace in a dual-fuel setup. When comparing to your existing AC, expect better dehumidification in cooling mode and more consistent warmth in shoulder seasons.

System types and configuration options

The most common option is the air-source heat pump (ASHP), which uses outside air as the heat source in winter and a condenser for cooling in summer. Ground-source or geothermal heat pumps (GSHP) tap into the earth or groundwater and generally offer higher efficiency but require more space and upfront investment. For homes with existing ducts, a ducted ASHP can reuse your current layout, while ductless mini-splits provide targeted cooling/heating without ductwork. Hybrid or dual-fuel configurations pair a heat pump with a furnace to boost performance in very cold weather. Each setup has pros and cons related to climate, installation complexity, and long-term operating costs.

Home readiness: climate, ducts, and electrical

Before you upgrade, evaluate your climate. In milder winter regions, a standard ASHP may meet most heating needs efficiently. In colder areas, you may require a heat pump designed for low temperatures or a dual-fuel system. Ductwork should be inspected for leaks and proper sizing; leaky ducts can negate efficiency gains. Electrical capacity must support the new equipment; older panels may require upgrades. A licensed technician will perform a load calculation and verify that your wiring, breakers, and outdoor unit clearances meet code requirements. Proper insulation and sealing improve overall performance and reduce heat loss.

Planning the upgrade: sizing, permits, and budgeting

Accurate sizing is essential for comfort and efficiency. A Manual J load calculation helps determine the right heat pump size for your home, accounting for insulation, air leakage, and window orientation. Permitting and local codes govern installation work, and many regions offer rebates or incentives for energy-efficient upgrades. While precise price details vary by region and contractor, expect significant differences between component choices (air-source vs geothermal) and installation complexity. Your installer should present a transparent plan, including equipment specs, duct modifications, and service timelines. Always prioritize equipment with a good warranty and proven performance metrics.

Installation overview: what happens during replacement

A typical upgrade involves removing or repurposing the old outdoor condenser, installing the new heat pump outdoor unit, connecting refrigerant lines, and installing the indoor air handler or ductless units. The technician will evacuate and recharge the refrigerant, test electrical connections, and calibrate the thermostat and controls. A thorough leak test and airflow verification ensure the system operates to specification. After installation, you should receive a commissioning report detailing system pressure, temperature split, and efficiency expectations. Expect thorough testing across cooling and heating modes, plus recommendations for air filtration and zoning if applicable.

Maintenance, efficiency, and common myths

Regular maintenance extends heater life and preserves efficiency. Schedule seasonal inspections, replace or clean filters, and ensure outdoor units are clear of debris. Heat pumps excel in efficiency, but myths persist—some homeowners fear poor performance in winter or believe heat pumps are universally expensive to operate. In reality, performance depends on proper sizing, climate, insulation, and usage patterns. With professional installation and routine upkeep, many households experience comfortable temperatures and lower operating costs year-round.

Tools & Materials

- HVAC service tools set(Includes manifold gauge set, refrigerant scales, and vacuum pump adapters)

- Digital multimeter / voltage tester(For electrical checks and sequence testing)

- Screwdrivers and wrenches (Phillips and flat)(Assorted sizes for unit connections and mounting)

- Safety gear (gloves, goggles, ear protection)(Personal protective equipment for refrigerant work and electrical tasks)

- Duct sealing materials (mastic, foil tape)(To seal leaks and improve efficiency if existing ducts are compromised)

- Thermal imaging camera (optional)(Helps identify insulation gaps and duct leaks from a distance)

- Electrical service upgrade kit (if needed)(Depending on panel rating and load calculation; may require electrician)

Steps

Estimated time: 1-4 days

- 1

Define goals and assess suitability

Clarify whether you want year-round heating and cooling in one system, and check if your climate supports a heat pump with confidence. Consider current ductwork and space for the outdoor unit. This sets the direction for type and size.

Tip: Document current energy bills to benchmark post-upgrade savings. - 2

Obtain a professional load calculation

Have a licensed technician perform a Manual J load calculation to size the system correctly. Improperly sized units cause inefficiency and comfort issues. This step also identifies ductwork improvements that may be needed.

Tip: Ask for a written report with recommended unit sizes and duct modifications. - 3

Choose heat pump type and configuration

Select between air-source, geothermal, or a ductless option based on climate, space, and budget. Decide if you’ll use ducted or ductless configurations and whether a dual-fuel approach is beneficial.

Tip: Consult with your installer about climate-specific performance ratings (HSPF, COP). - 4

Evaluate ductwork and ventilation

Inspect ducts for leaks and ensure proper sizing. Duct repairs or sealing can dramatically improve system efficiency and comfort. Consider zoning if the home has varying heating needs by area.

Tip: Seal leaks before installing the new system to maximize efficiency. - 5

Plan electrical requirements

Verify electrical service capacity and ensure the panel and wiring meet the new unit’s load. Install dedicated circuits if needed and plan for surge protection or a future smart thermostat.

Tip: Coordinate with a licensed electrician to ensure safe, code-compliant wiring. - 6

Secure permits and incentives

Check local codes and secure necessary permits. Explore rebates and incentives for energy-efficient upgrades, which can offset upfront costs. Your installer should help identify eligible programs.

Tip: Keep all permit records and rebate confirmations for future reference. - 7

Install the outdoor and indoor units

Remove the old condenser if required, position the new outdoor unit with proper clearances, and connect refrigerant lines to the indoor air handler or ducted system. Ensure proper electrical connections and drainage for condensate.

Tip: Avoid placing the outdoor unit near heat-producing equipment or high-traffic areas. - 8

Commission, test, and document

The technician will evacuate, recharge, and test refrigerant charge, airflow, and thermostat operation. Review performance in cooling and heating modes and adjust controls as needed.

Tip: Request a commissioning report that documents setup and measured performance. - 9

Plan maintenance and future-proofing

Schedule seasonal inspections, filter changes, and component checks. Discuss potential future upgrades, such as progressive zoning or smart controls, to maximize efficiency.

Tip: Set calendar reminders for annual maintenance.

Common Questions

Can I reuse existing ductwork with a heat pump?

Reusing ducts is possible if they are in good condition and properly sealed. A professional will test for leaks and assess whether ductwork needs repair or replacement to maintain efficiency.

Yes, but ducts must be checked for leaks and condition; a pro will confirm feasibility.

Do heat pumps work well in cold climates?

Many heat pumps perform well in moderate cold, but very cold regions may require a dual-fuel setup or models rated for low temperatures. A technician can tailor the system to your climate.

In colder climates, you may need a heat pump designed for low temps or a backup heat source.

What is a dual-fuel system?

A dual-fuel system combines a heat pump with a furnace to provide reliable heating in very cold weather while saving energy when temperatures are milder.

It pairs a heat pump with a furnace to handle extreme cold efficiently.

How long does installation typically take?

Installation usually spans 1-4 days, depending on home size, ductwork needs, and electrical upgrades. Your contractor will provide a precise timeline during the quote.

Expect about 1 to 4 days for installation, depending on the project.

Are heat pumps more expensive to install than traditional A/C?

Upfront costs can be higher for heat pumps, especially geothermal or dual-fuel setups. Long-term savings come from lower heating costs and improved efficiency.

Upfront costs may be higher, but long-term energy savings can offset them.

What maintenance does a heat pump require?

Regular filter changes, annual professional inspections, and outdoor coil cleaning keep performance high. Schedule service before peak seasons for best results.

Change filters regularly and schedule annual checks for peak efficiency.

Watch Video

The Essentials

- Assess climate and ductwork before choosing a heat pump.

- Size the system with a formal load calculation.

- Plan electrical needs and permits early.

- Professional installation is essential for performance.